The Intellicess core product, Sentinel RT®, is a powerful and fully customizable backend engine that can be tailored to the specific needs of your unique ecosystem and workflows. Its capabilities are designed to close the gap between technical limit drilling on paper and the actual drilling time and costs incurred in the field. Sentinel RT® does this by identifying the causes of nonproductive time (NPT) and invisible lost time (ILT) through time-series pattern recognition algorithms and real-time drilling state analysis. It also automates traditionally manual processes, which facilitates workflow optimization and frees personnel to attend to more critical drilling tasks. Sentinel RT® can also reduce the technical limit itself by enabling multiwell analysis to identify optimal equipment and bit choices and by defining the limits of important drilling parameters. Below we showcase how Sentinel RT® has been used by our customers.

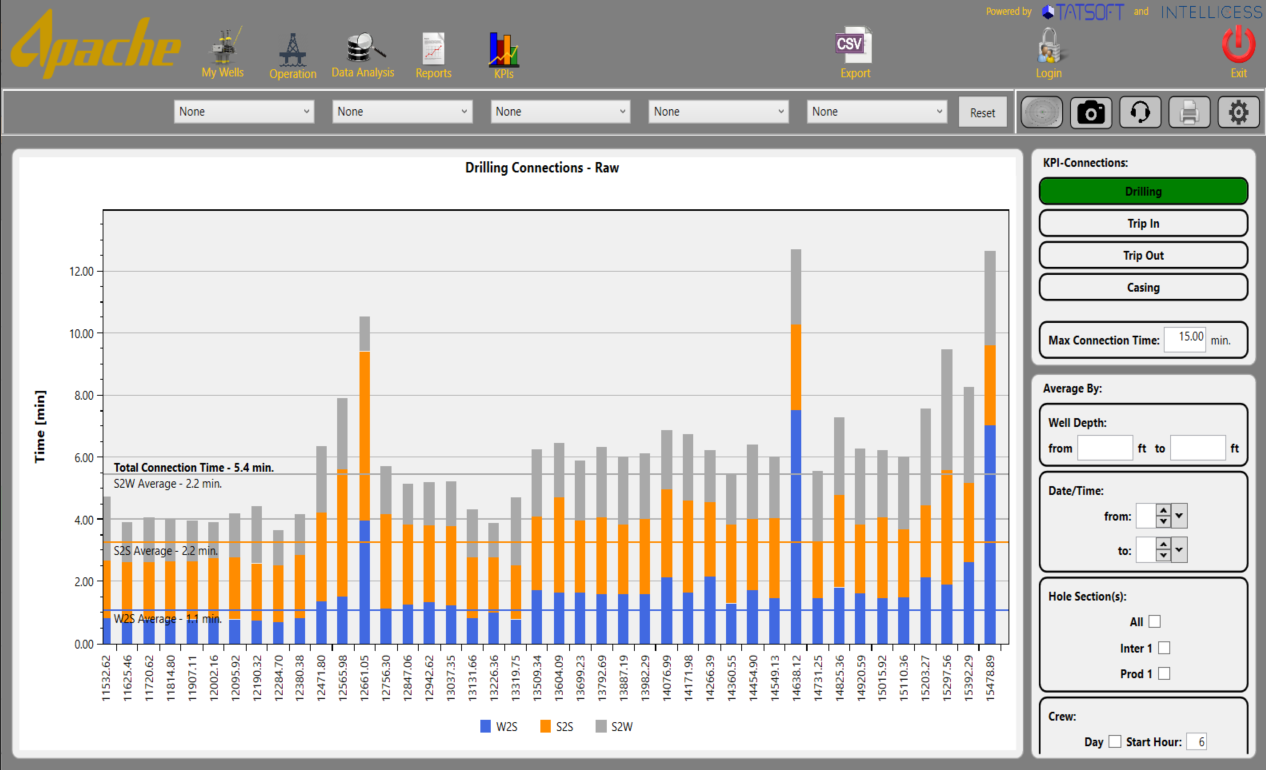

Invisible lost time (ILT) can waste resources, cause budget overruns and can account for more than 30% of total drilling time. ILT occurs when routine drilling operations, such as making connections, cementing and other so-called flat time procedures are performed inefficiently and are especially difficult to detect and quantify during.

When identified through real-time data monitoring, the causes of ILT, during both drilling ahead and flat time operations, can be corrected with relative ease and can reduce the cost of drilling a well significantly However, traditional methods for gathering relevant drilling data into a format suitable for ILT identification are intensely time-consuming and expensive.

The Intellicess backend engine, Sentinel RT®, eliminates these time and cost barriers through a sophisticated data cleansing and aggregation module that fully automates the data analysis process. The system then enables users to identify inefficient crews or drilling problem areas through highly informative ILT reports, which may be generated by the user through the click of a button at any time during the drilling process.

Operators can significantly improve drilling rates and reduce costs by eliminating operational inefficiencies that generate invisible lost time (ILT) and equipment failures that result in costly nonproductive time (NPT). To accomplish these objectives, drillers must be able to make drilling parameter adjustments in real time.

However, the ability to recognize and make such changes quickly is limited by the reliability of surface and downhole measurements and by the capability of humans to aggregate multiple streams of data in real time.

The Sentinel RT® drilling optimization system is designed to eliminate these hurdles by incorporating a Bayesian network into the drilling rig data aggregation system. This network-based system identifies drilling dysfunctions in real time through its unique ability to compare the movement of sensor data to model predicted values.

This method combines dysfunction identification with MSE tracking to create a single normalized quantity or drilling optimization index. The driller can then use the index to change parameters and correct conditions that might otherwise have resulted in significant ILT and NPT.

The system also provides recommended changes to such parameters as weight-on-bit or rotary speed through a visualization tool called ‘Cone Drilling®.’ This unique feature creates a cone-shaped shaded area on a customized graphical display of drilling parameters, such as WOB vs RPM, to clearly convey to the driller recommended parameter adjustments.

Current slide drilling practices rely heavily on the experience and training of directional drillers to identify and correct dysfunctions by adjusting drilling parameters in real time. These changes are designed to produce a smooth, readily accessible wellbore.

A quality wellbore greatly reduces the potential for invisible lost time (ILT) that result from reentry difficulties encountered during casing, cementing and completion operations. It also helps ensure against nonproductive time (NPT) caused by such events as stuck pipe that often leads to expensive side-tracking, or by difficulties tripping pipe or cementing. In the end, a smooth wellbore with minimum undulations optimizes production flow.

But adjusting parameters in response to changing well conditions requires the directional driller to monitor numerous dysfunctions simultaneously, which is too complex a task to be done manually. To remove the resulting uncertainty inherent in modern directional drilling, Intellicess has created the first method designed specifically for diagnosing drilling dysfunctions in real time while slide drilling.

The Sentinel RT® Bayesian network-based real-time drilling advisory system provides remote directional driller assistance. It uses evidence derived from transient drilling data trends to simultaneously infer the probability that any of five monitored dysfunctions – buckling, high friction, poor toolface control, stick slip and bit bounce – is occurring.

As dysfunction probabilities are calculated, an algorithm determines necessary action that the driller can implement to correct the adverse condition. Corrective actions are output in the form of simple drilling parameter changes shown on a customizable graphical display.

Traditional morning reports are created through labor-intensive and time-consuming efforts to gather and select data with which to summarize the day’s drilling operation. Because morning reports are created manually, they are also inefficient and often do not include critical information.

Sentinel RT® provides a system that constantly processes and stores drilling data and automatically creates a summary report of all the information processed though out the day.

The report includes key performance indicators (KPI) drillers and drilling engineers can use to judge the quality of operations, such as drilling and connections. The Sentinel RT® summary report also indicates to the driller the presence of sticky spots, hole cleaning inefficiencies and other possible problem areas that they may encounter during subsequent drilling operations.

The fully automated daily report is sent out to concerned parties each day at a previously specified time. When the well reaches TD, an end-of-well report may also be automatically generated and sent to appropriate personnel. KPIs can also be used to execute smart contracts between parties, such as the rig contractor and the operator.

Drilling information has long been manually entered into a database system, such as WellView™ and OpenWells™, where it is stored as a reference for future drilling operations. While these data provide operators with a powerful tool, creating them is typically a tedious and time-consuming process.

To relieve operators of the burdens associated with performing this critical task, Sentinel RT® calculates much of the relevant drilling information in real time. Then, by using connectors built for the purpose, these calculated values can be directly pushed into WellView™, OpenWells™ or the operator’s own database. This allows operators to better manage workflows by relieving rig personnel of report writing duties and freeing them to focus on other essential operational tasks.

High torque and drag (T&D) levels are often the limiting factor in lateral drilling lengths and the root cause of increased costs, drilling time and nonproductive time (NPT). The ability to counter its impacts requires drillers to measure T&D in real time and compare the data to a T&D model. This process requires merging up-to-the minute and contextual data of dissimilar quality, as well as repeated model calibrations to achieve reliable results.

Because it is so complex, drilling engineers often feel they do not have the time to build a T&D model or to gather and apply real-time data to it, and often choose to leave the process out of their workflow entirely. To address these difficulties, the Sentinel RT® system automatically generates T&D models using both contextual information and real-time drilling data that tracks for pick-up, slackoff and rotating off-bottom weights. It then automatically alerts rig and office personnel of overpull and underpull events and records the depths at which they are occurring.

While tripping, these early warnings help drillers avoid excessive pipe wear, drilling equipment damage and stuck pipe, all of which can lead to catastrophic failure and costly NPT. The system determines openhole and casing friction factors and can perform model calibration. It also uses real-time broomstick plotting and field data comparison to help with subsequent casing run planning and design.

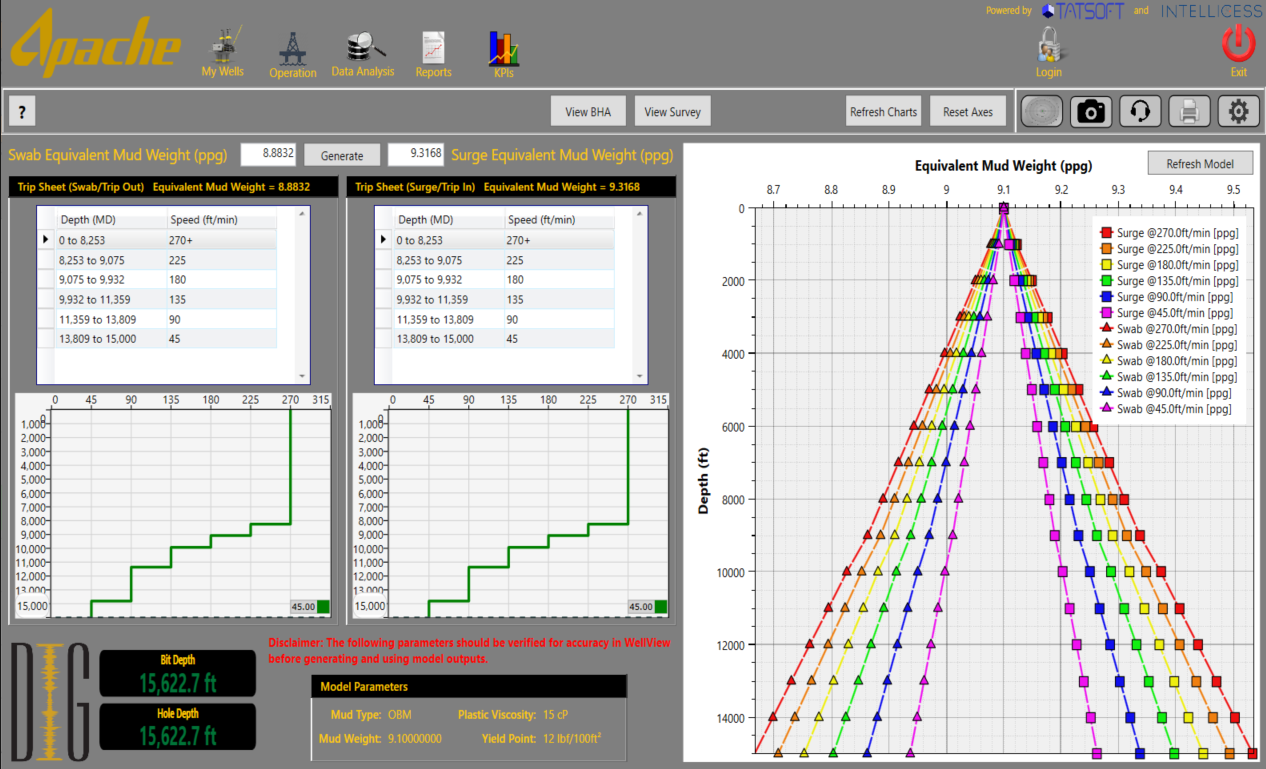

Inappropriate drillstring tripping speeds may cause excessive fluid displacement and pressure oscillations in the annulus. These swab or surge events can result in wellbore pressures that are lower than the pore pressure (PP) or greater than the fracture gradient (FG), which lead to kicks or lost circulation.

Remedial operations to address either of these conditions typically results in considerable nonproductive time (NPT) as drillers cease drilling ahead and take steps to bring the well back into balance.

The Surge & Swab model implemented within Sentinel RT® provides drillers with real-time downhole pressure predictions during tripping. Using a hydraulics model, the system determines how the pressure varies as the drill string is moved inside the wellbore. This is compared to the PP and FG at that depth to ensure that swab and surge do not occur and that pressures remain within the PP/FG window.

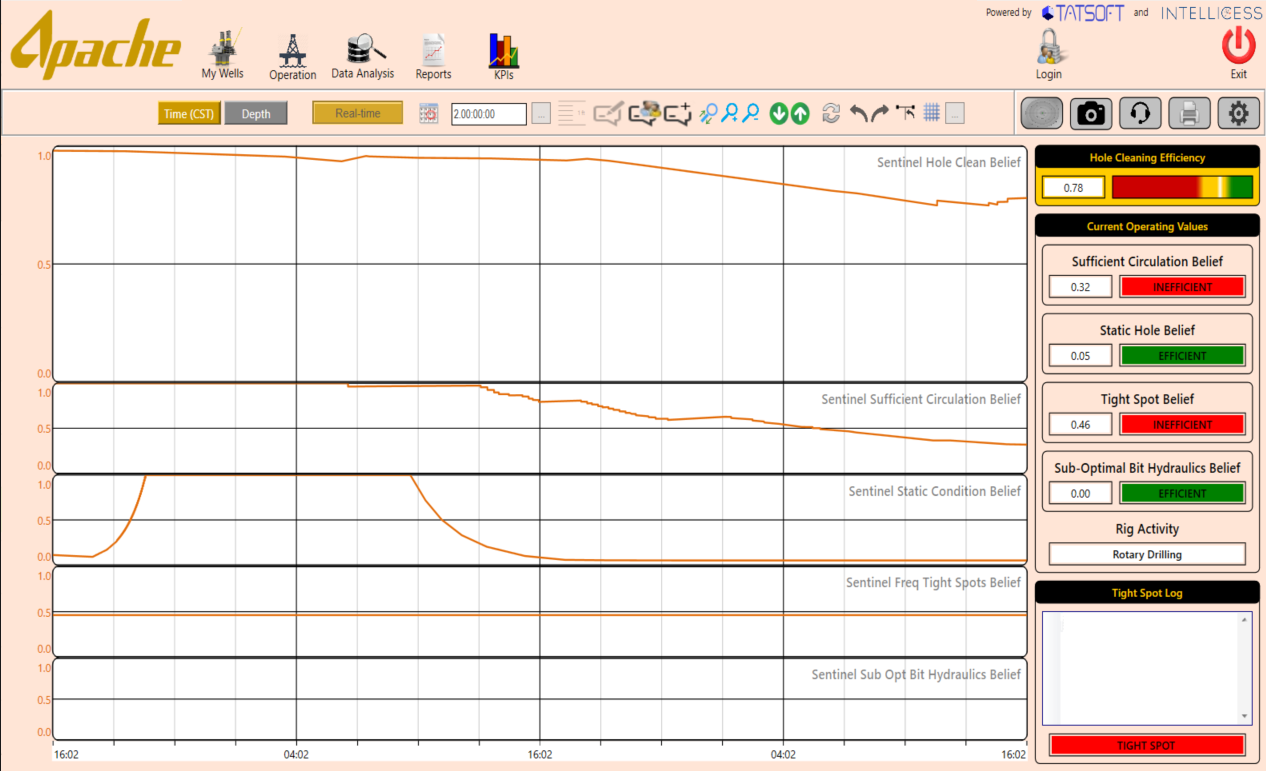

Engineers have traditionally relied on cuttings transport models for monitoring and controlling the status of wellbore cleaning. However, because they are sensitive to inputs that are often based on assumptions and complex rheology that is difficult to define, cuttings transport model results are uncertain and may lead to poor hole cleaning decisions.

The immediate consequences of poor hole cleaning can be nonproductive time (NPT) in the form of stuck pipe and often prolonged and costly fishing or side-tracking operations. Poor hole cleaning may also cause invisible lost time (ILT) when inaccurate models lead drillers to use inappropriate tools that result in poor penetration rates.

The Intellicess Sentinel RT® system applies a more robust symptom-based methodology to hole cleaning that tracks key events for prolonged periods of time. These events include circulation rates, hydraulic impact forces, active hole conditions, tight spots and hole angles.

The system uses a Bayesian network to aggregate key sensor inputs, contextual data and predictions from hydraulic modeling. Cumulatively, these inputs generate a probabilistic belief system and a model that generates belief values of between 0 and 1, which indicate hole cleaning problems.

The network also provides the driller clear indications that hole cleaning actions are needed and why they are needed before they require expensive and time-consuming solutions.

Drillstring washouts immediately impact drilling hydraulics and may ultimately lead to twist-offs and expensive fishing and sidetracking operations and significant nonproductive time (NPT). Traditionally, detecting drillstring washouts has been left to methods that rely on standpipe pressure and pump rates or MWD sensor data. However, because of poor quality sensor data and various factors that can affect flow and pressure measurements, these methods are often unable to recognize the existence of these conditions in time for drillers to take corrective actions to prevent catastrophic failures.

The Intellicess Sentinel RT® system is a real-time system capable of detecting drill string washout by combining a physics-based hydraulics model with trend monitoring. It uses a Bayesian network to aggregate key sensor inputs, contextual data, and predictions from hydraulic modeling, which the system uses to determine a probabilistic belief system and a model that generates values of between 0 and 1. These values indicate specific drilling (drillsting washout), equipment (pump) and sensor failures.

The network includes several event types, such as a drop in pump pressure with constant stroke rate and a decrease in hydraulic coefficient, and their associated probabilities. A real-time alerting system sends emails to appropriate personnel with information about the alert and a real-time diagnostic screen can be used to monitor the alerts at the rig site.

Sentinel RT® keeps a record of various events and their attributes as they occur during drilling operations. This enables convenient review of these events on the well path or on a vertical strip chart.

Items tracked include drilling and tripping dysfunctions and events such as washouts, kicks, lost circulation, mud motor stalls, motor use above rating, hole cleaning problems downlinks and others. Inefficient Weight-to-weight and slip-to-slip operations are also tracked. The record of these events is particularly useful for managing workflow when reviewing the previous 12 hours of activity and during crew change.

The process also eliminates subjectivity with respect to major operational and is a real-time digital twin of events enabled by consistent and repeatable pattern tracking.

The early detection and accurate characterization of kicks and lost circulation events, which often lead to significant non-productive time (NPT), is critical to efficient drilling operations. Traditional detection methods, absent costly flow-in and -out sensors, use pit volume trends to detect mud influx and loss.

However, because external mud addition and removal to the pits is not monitored, volume and gain trends may trigger false kick or lost circulation alarms.

By using the Sentinel RT® Bayesian network to aggregate trends detected in time-series data with events identified by natural language processing of drillers’ memos, the accuracy and robustness of kicks and lost circulation detection is greatly improved.

This approach identifies and quantifies abnormal losses and gains and automatically accounts for and monitors other contributing factors to pit volume gain, such as those that occur during connections and mud additions.

Real-time analysis of driller memos provides context to pit volume trends and thus further reduces the number of time-consuming false alarms and enhances safety and rig site awareness. The system greatly reduces NPT by alerting the driller that corrective action is required before an event leads to expensive, time-consuming remedial operations.